Your Full-Service Partner, From End-to-End

SCI prides itself in being a full-service partner to all our customers, so it is important to offer complimentary services to our main calibration and clean room offerings. From measurement and control commissioning to emergent repair and measurement and control system installations, we will ensure you are always mission-ready.

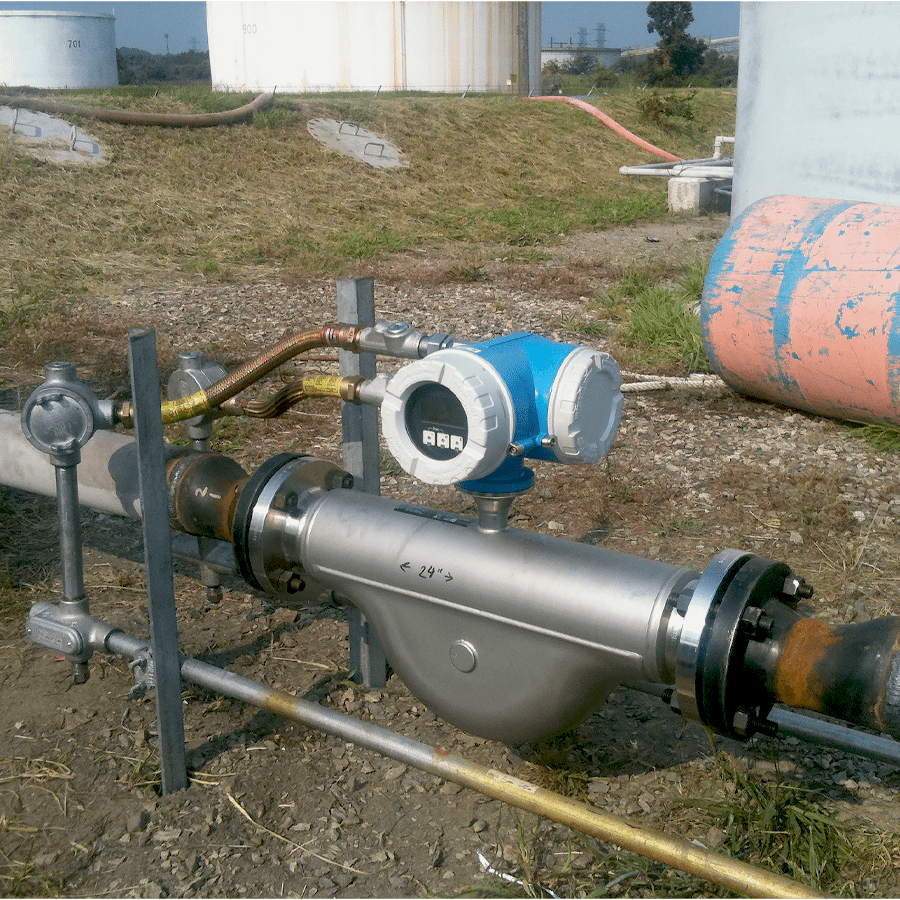

Commissioning Automation Measurement and Control Devices

Standard Calibration, Inc. (SCI) can commission your process automation measurement and control devices while adhering to your facility's process requirements.

Our broad experience means we’re capable of commissioning:

- Transmitters—level, differential, gage, absolute pressure, and temperature

- Flow meters—coriolis, vortex, electromagnetic, ultrasonic

- Tank Level Indicators (TLIs)—magnetic reed/float, radar/TDR, DP transducers, bubbler, and capacitance

- Analyticals selection and configuration—alkalinity, conductivity, pH/ORP, dissolved oxygen, and more

MIL-SPEC Packaging and American Society for Testing and Materials Standards (ASTM)

SCI offers Military Specification (MIL-SPEC) packaging—a set of rules that use the American Society for Testing and Materials (ASTM) standards. These are the international standards adopted by most countries and other Military Standards (MIL-STD) that ASTM International adopted and updated for industrial and commercial use.

Our team of experts uses ASTM and MIL-STD required cardboard boxes, in addition to manufacturing wood boxes and shipping crates, which are sized, shaped, and cushioned to protect your product during transport and storage.

Packaging that requires ISPM 15 will be marked with our designated stamp of approval for international export.

We work together with the Defense Contract Management Agency (DCMA), the agency of the government that does all of the inspection of items purchased by or for the military, to ensure that all of our packaging meets or exceeds the requirements in any given contract.

Military packaging expertise includes:

- MIL-STD-2073 Packaging—Standard practice for military packaging

- MIL-STD-129 Marking—Uniform military marking for shipment and storage

- MIL-STD 130—Marking criteria

- ASTM D3951

- Individual Unit Identification (IUID) labels

- Radio Frequency Identification (RFID) labels

Rapid Response and Emergent Repair

We understand that our customers face unique challenges every day. SCI's factory-trained and qualified technicians are ready to provide rapid response support to emergent requirements wherever, whenever.

SCI exceeds all of the required industrial insurance coverage and maintains an EMR rating below the industry requirement, and offers direct support to your facility during critical engineering evolutions.

Technical services include, but are not limited to:

- Calibration (in-house and on-site)

- OEM technical support

- Troubleshooting

- Outage support

- E&I technicians

- I&C technicians

- Welding

- Pipe fitting

- Installation and removal teams

- System flushing

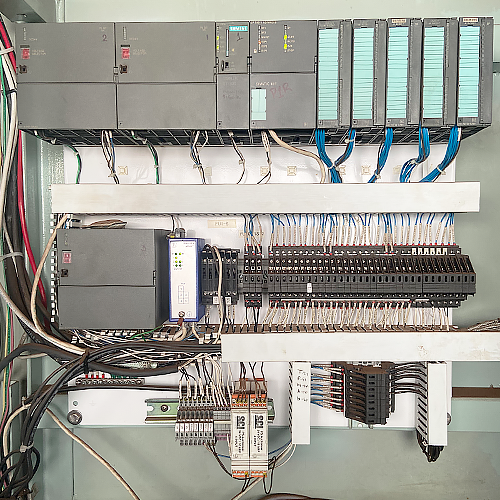

High-Quality, Cost-Effective Engineering Solutions

Our engineering and management staff are proven professionals dedicated to providing customers with innovative, high-quality, and cost-effective engineering solutions.

Below are just a few examples of recent design/build projects accomplished by SCI:

- Designed and built automated test stands for the measurement of pressure, torque, and flow.

- Designed flow- and level-measuring systems; awarded balance of plant instrumentation and controls for Dominion's Warren County Power Station.

- Re-designed and configured a flow-measuring system on Green Liquor Flow in a lime kiln, which enabled the mill to get multiple measurements at a greater accuracy than the previous design.

- Engineered, designed, and built the Shipyard and Naval Auxiliary Instrumentation Laboratory (SNAIL) for all USN CVN Mil-Spec instrumentation.

- Calibrated, cleaned, and tested NASA Launch Cart piping and instrumentation.

- Designed, engineered, built and installed shipyard floating drydock tank level indicating hog and sag monitoring system.

- Designed, fabricated, and tested the software and mechanical emergency shaft laser and magnetic tachometer for USN aircraft carriers—eight different kits in total for Ford class CVN.

- Design specialized pressure and temperature calibration test kits for use on US Navy ships (Includes kits for hydraulics, pneumatics, and O2 clean systems)

Your Installation Partner for Measurement and Control Devices

SCI can install your process automation measurement and control devices while adhering your facility's process requirements.

SCI has extensive experience in control and monitoring system installation, and our support services include, but are not limited to, installation of:

- Pressure sensors—gauges and transducers

- Temperature sensors—thermometers, RTDs, and thermocouples

- Transmitters—pressure and temperature

- Flow meters—coriolis, vortex, electromagnetic, ultrasonic

- Tank level indicators, magnetic reed/float—radar/TDR, DP transducers, bubbler, and capacitance

- Analytical selection and configuration—salinity, conductivity, pH/ORP, dissolved oxygen, etc.

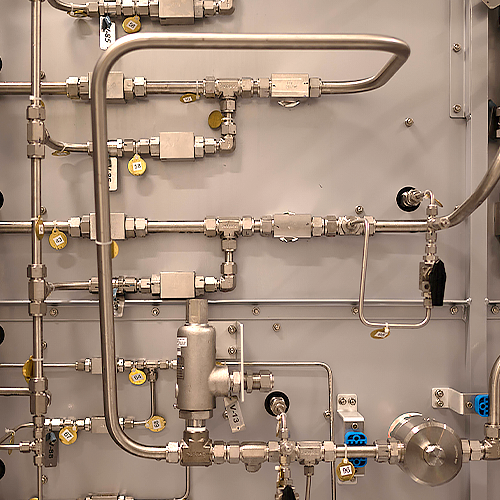

Repair and Overhaul of Pneumatic Control Systems

Since opening our doors in 1989, we have remained an industry leader in the repair and overhaul of pneumatic control systems. SCI has continued to develop core capabilities in the repair of piping systems and valves.

Our services include, but are not limited to:

- In-shop and shipboard welding, brazing, pipefitting

- Valves

- Overhaul and test of shutoff/control/reducing/relief valves

- Overhaul and test of air and hydraulic reducing/regulating manifolds

- System repair, cleaning, flushing, and certification (as required)

- Breathing and Critical air systems— \in accordance with MIL-STD-1622

- O2/N2 systems in accordance with MIL-STD-1330

- Chilled water/cooling water systems

- Diver's Life Support Systems

- HP/MP/LPair systems

- Deluge system flushing

- Nuclear applications

- Hydrostatic testing

- Cylinder cleaning and flushing

- High and low pressure hoses

- Tubing and piping systems

The SiP Program focuses on select critical environmental control devices that require repeat calibration, recertification, and usage configuration management.

Fully calibrated and accepted inventory-controlled material will be maintained at both the customer's and SCI’s locations for immediate or just-in-time delivery of sensors, PLCs, switches, breakers, safety equipment, and other critical environmental instruments.

Services include:

- Application engineering

- Inspection

- Preservation

- Labeling

- Packaging

- Material

- Handling/shipping

- Software (firmware) and hardware upgrades

- Environmentally controlled inventory at SCI

- Secure

All services coincide with the appropriate standards and industry knowledge for testing, shelf life, calibration, transportation, and storage under ANSI, OSHA, ASTM or other industry standards.

Outage and Shutdown Technical Services

SCI can support your outage or shutdown with services such as:

- Calibration (in-house and on-site)

- Troubleshooting

- Repair

- OEM technical support

- E&I technicians

- I&C technicians

- Installation teams

- Removal teams

- System flushing

- Welding

- Pipe fitting

With SCI's understanding of power generation, chemical processing plants, pulp and paper mills, pharmaceutical plants, food and beverage manufacturing facilities, and water and wastewater treatment plants, SCI can support projects ranging from annual power generation outages of turbines and boilers to capital upgrade projects of pharmaceutical plants.

SCI works closely with its clients to ensure the proper policies and procedures are followed for each facility.

SCI has established accounts and holds safety certifications with some of the nation's leading third party safety training organizations. SCI meets or exceeds all of the required industrial insurance coverages and an EMR rating below the industry requirement, and can support your outage or shutdown safely and on short notice, no matter how big or small.

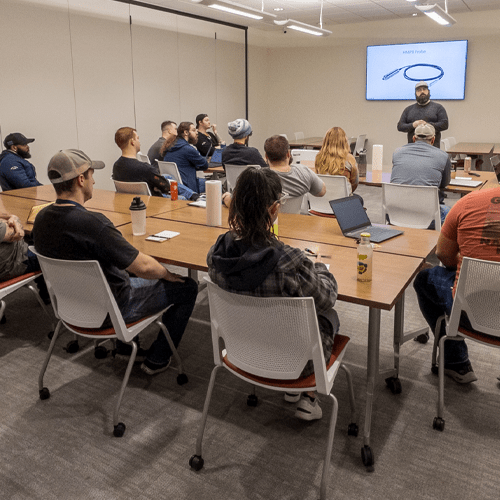

Monitoring and Control System Instruction and On-the-Job Training

SCI offers a wide range of training support services to our customers, including formal instruction, curriculum development, in-shop and on-site on-the-job training, and technical oversight in the following areas:

Electrical monitoring and control system fundamentals:

- Use of test, measurement, and diagnostic equipment

- Equipment/system testing and inspection

- Fault isolation

- Material procurement

- OEM repair standards and best practices

- Alignment/calibration

- Use of technical references and procedures

- Quality workmanship

Because we completely understand the critical nature of the systems we repair, we continually strive to not only provide superior results, but also to ensure our customers have the tools and knowledge necessary to maintain their systems at optimum condition.

Need a quote for products or services? Click here to submit a Request For Quote.Request A Quote