In-Shop Precision Cleaning, Hydrostatic/Proof Testing and Flushing

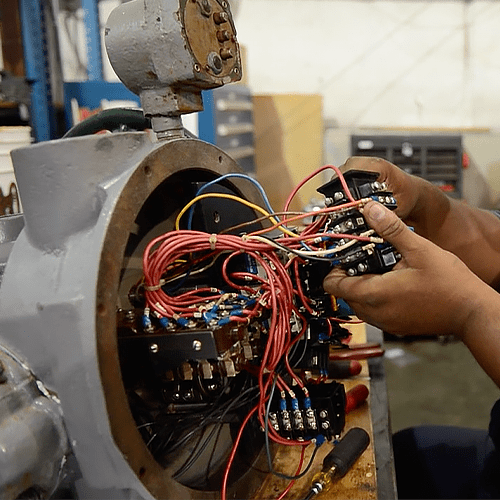

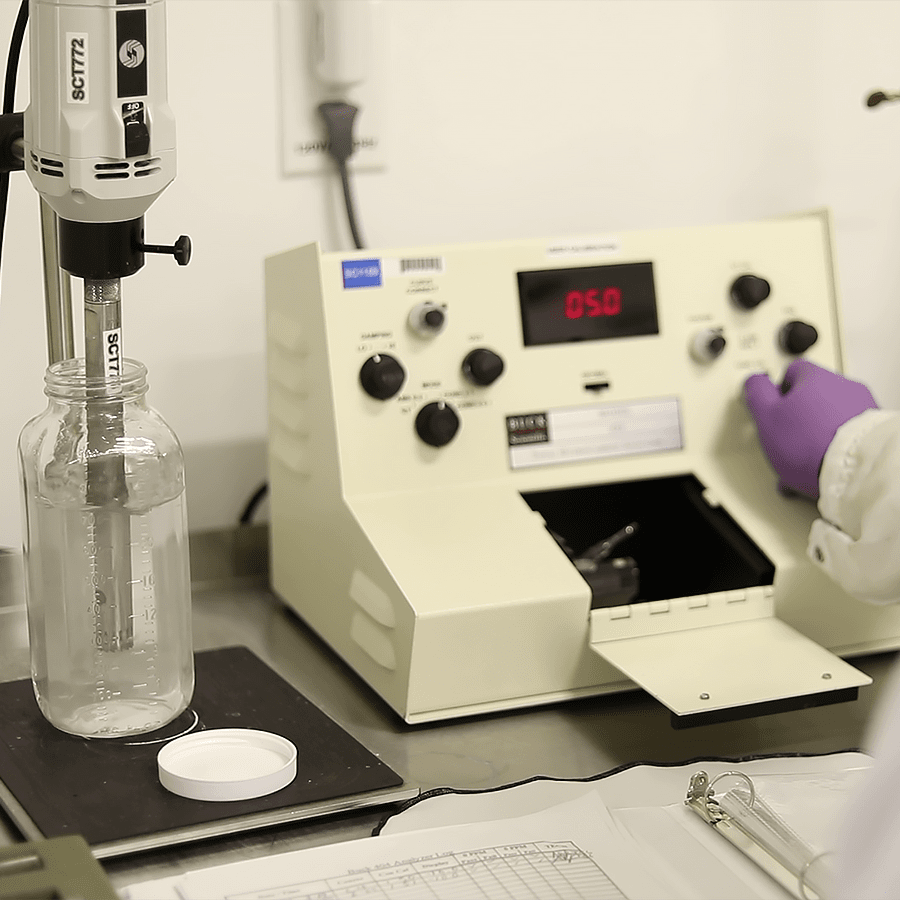

SCI knows precision cleaning services. NAVSEA OOC4 Diving Systems Certification Division has certified SCI’s 600-square-foot controlled area and 500-square-foot clean room facility These facilities are capable of performing in-shop precision cleaning, hydrostatic/proof testing, flushing, certification and packaging of oxygen/nitrogen systems instrumentation, piping/hoses, and components. Work is accomplished to meet customer requirements including those of MIL-STD-1330 and CGA G4.1 for oxygen systems, MIL-STD-1622, IEST-1246 for compressed air/nitrogen systems, breathing air systems, instrumentation, piping, and components, and MIL-STD-767 cleaning for nuclear applications.

SCI’s Navsea Joint Navy Audit Certification Team (JNACT) accredited and commercially certified Oxygen Instrumentation Calibration Room (OICR) and certified Oxygen Clean Workers are approved for the cleaning and calibration of oxygen and compressed gas instrumentation.

Additionally, SCI has the required equipment for onsite oxygen and critical gas system instrument calibration and oxygen and compressed gas system cleaning and flushing.

Comprehensive Clean Room Service Capabilities

The above-listed services and capabilities include but are not limited to:

- Self Contained Breathing Apparatus (SCBA) charging stations, piping, and components

- Ship oxygen, nitrogen, and breathing air system piping and components

- Pressure gauges

- Valves, relief valves, and regulators

- O-rings and filters

- Cylinders

- Umbilicals

- Emergency Breathing Air Compressors (EBAC)

- Emergency Escape Breathing Devices (EEBD)

- Air Booster Pump Assemblies (ABPA)

- Breathing Air Reducing Stations (BARS)

- High-Pressure Breathing Air Compressor (HPBAC)

- Primary Air Supply Pack (PASP)

- SKA-PAK flow testing

- Diver's Life Support System (DLSS)

Oxygen Clean Services, Overhauls, Repairs and Recertifications

SCI performs various services, overhauls, repairs, and recertifications within the Scope of Certification (SOC) on oxygen clean and breathing air equipment. We support both Divers Life Support System (DLSS) and specialized equipment used by US Navy Special Operations Command (WARCOM) and Marine Corp Special Operations Command (MARSOC). Our spectrum of work covers services as simple as a clean gauge calibration or complex as a complete air system rebuild.

Our skilled and trained technicians can perform preventative maintenance, repairs, or overhauls on the following equipment:

- Clean gauge calibration

- Breathing air compressor

- Hyperbaric chamber

- Haskel oxygen booster

- FADS III system

- HII electric oxygen booster

- HE/oxygen system

- Nitrox system

- HALO equipment

- Air Supply Rack Assembly (ASRA)

- Eddy current testing

- Umbilical pull testing

- Relief valve testing

- Light-weight Dive System (LWDS)

- Standard Navy Double Lock (SNDL)

- Seat, joint tightness, and drop testing

- Special Operations Charging Assembly (SOCA)

- Transportable Recompression Chamber System (TRCS)

- Seal Delivery Vehicle (SDV) and Mini-Sub (MSUB)

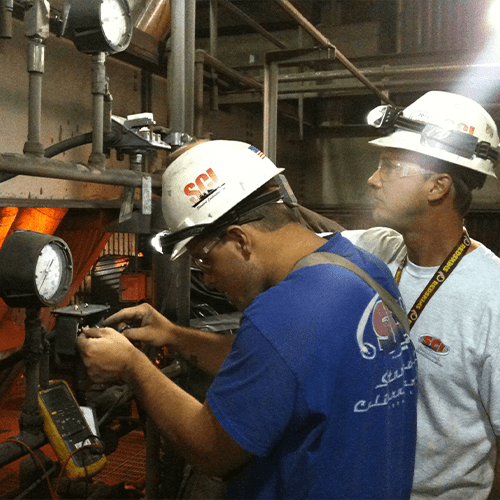

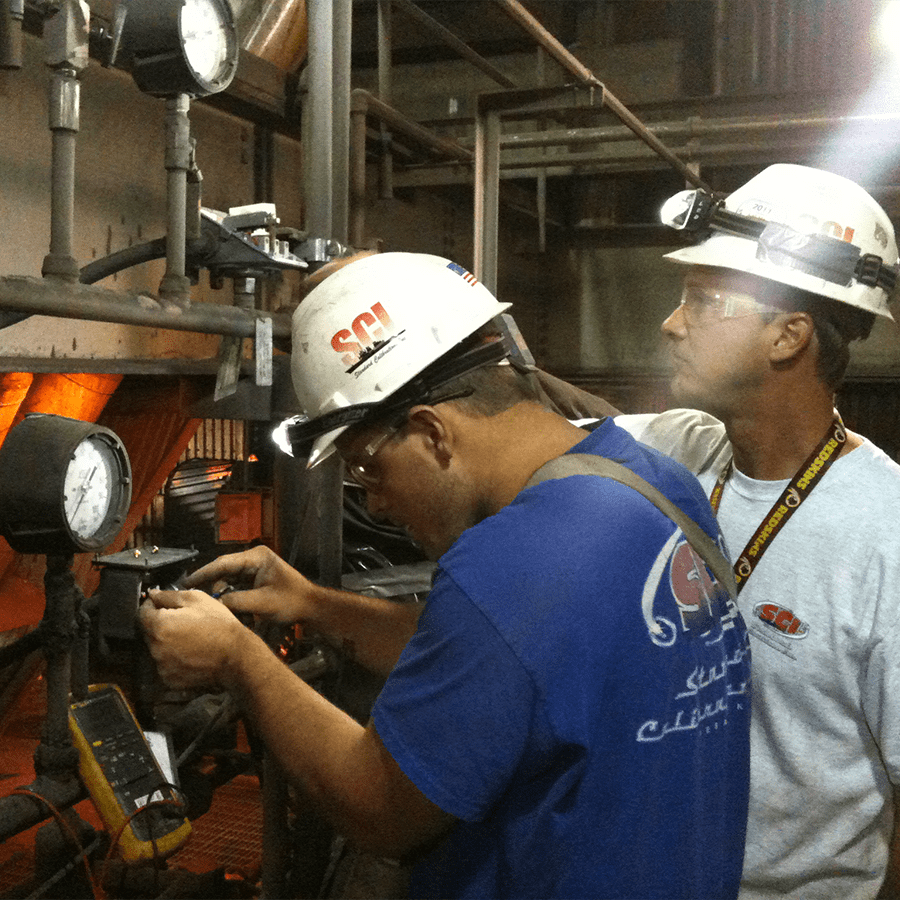

Navy Planned Maintenance System (PMS)

SCI's highly experienced and NAVSEA-certified staff is fully capable of accomplishing maintenance procedures outlined by the Navy's Planned Maintenance System (PMS) for various breathing air and oxygen systems.

We’re skilled in servicing a broad range of equipment, including damage control systems such as:

- Emergency Breathing Air Compressor (EBAC)

- Air Booster Pump Assembly (ABPA)

- Breathing Air Reducing Station (BARS)

- High Pressure Breathing Air Compressor (HPBAC)

- Primary Air Supply Pack (PASP)

- Self Contained Breathing Apparatus (SCBA) flow testing

Need a quote for products or services? Click here to submit a Request For Quote.Request A Quote

View our scope of accreditation

View our scope of accreditation